EpoxyCoated Mesh production process

EpoxyCoated Mesh production process

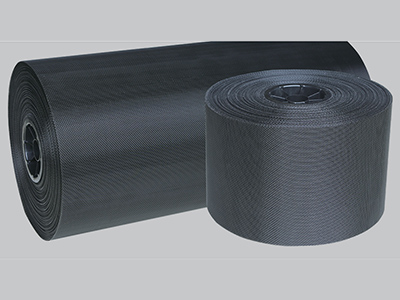

The formation of EpoxyCoated Mesh is achieved by electrostatic spraying to adsorb specialized EpoxyCoated Mesh resin powder onto the surface of a wire mesh woven from different metal substrates. At a certain temperature and time, the epoxy resin powder is melted, covering the surface of the substrate to form a fine protective coating.

YKM has an impeccable product function simulation laboratory, including paint film elasticity testing, pencil hardness testing, salt spray testing, powder adhesion testing, bending fatigue resistance testing, oil resistance testing, etc. It is mainly used for epoxy resin powder incoming inspection, product process quality testing, and new product development testing, with controllable product quality.

YKM has independently developed two production lines with excellent horizontal surface treatment, using far-infrared and natural gas hot air circulation methods for production. It has the characteristics of stable heat release, uniformity, easy operation, and environmental protection. The planned production capacity can reach 50000 square meters per day, with an annual output of about 15 million square meters. We have exhaust gas treatment equipment that meets the emission standards within the next 10 years, supporting post-processing capabilities such as slitting machines, slicing machines, splicing machines, and 30 high-speed original mesh weaving machines.